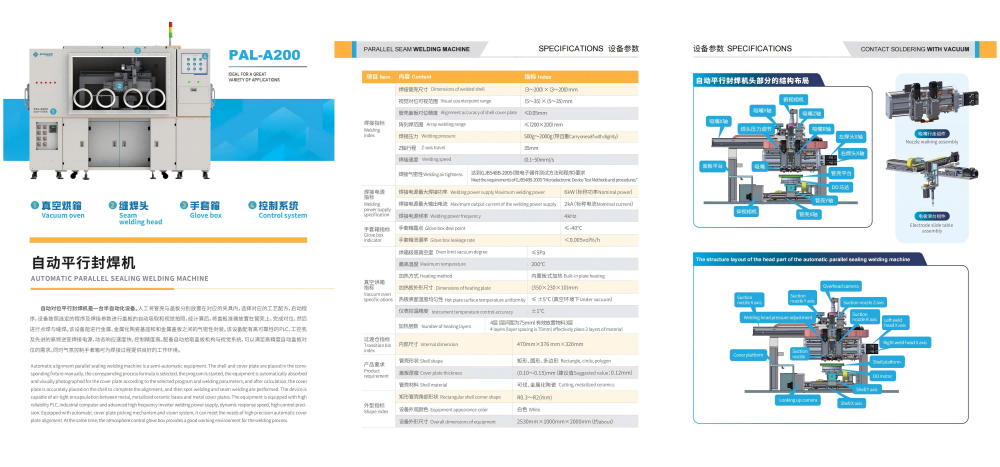

Automatic counterparallel sealing machine is a semi-automatic equipment. Put the pipe shell and cover plate in the corresponding fixture manually, select the corresponding process formula, start the program, and make the equipment automatically absorb and take visual pictures of the cover plate according to the selected procedure and welding parameters. After calculation, the cover plate is accurately placed on the pipe shell, complete the alignment position, and then conduct spot welding and seam welding. The equipment can carry out air tightness packaging between metal, metallized ceramic base and metal cover plate. The equipment is equipped with high-reliability PLC, industrial control machine and advanced high-frequency inverter welding power supply, with fast dynamic response speed and high control accuracy. Equipped with automatic pick-up cover plate mechanism and visual system, it can meet the requirements of high-precision automatic cover plate alignment. Meanwhile, the atmosphere control glove box can provide a good working environment for the welding process.

We chat